FF 6200-RBT

Play Video

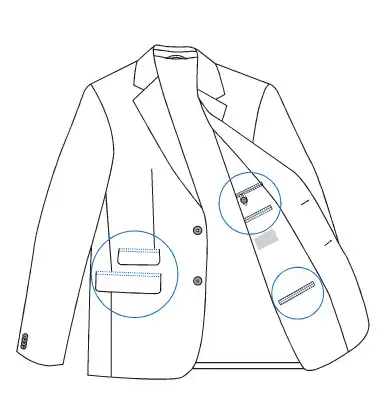

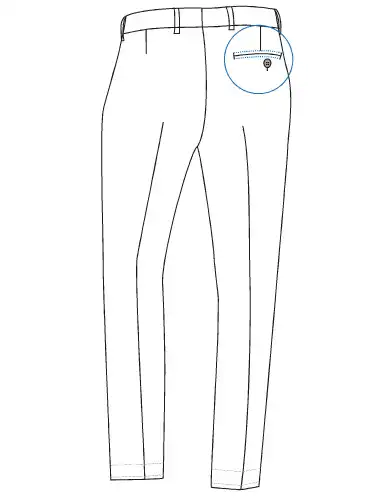

FF 6200-RBT version is an automated sewing unit far straight Cand optionally slantedlwelt pockets with the automatic feeding of breast welt pieces as standart and optionally automatic feeding of pocket facings and pockets bag. The second most important advantage of this robot is its cuting capability of the two edges of the welting piece which guarantees the stitched piece to be with zero pockering and best quality. This fully automatic version is far more suited far garments manufacturers with enough capacity to stitch one type of pocket welt on one unit only.

PERFORMANCES

250 - 300 pieces /1 hour2000 - 2400 pieces / 8 hour

TECHNICAL SPECIFICATIONS

- Brother Model C series direct-drive needle transport lock-stitch sewing head

- Easy to use Graphics on the Operator Panel with 50 Programming and Cycle Operation

- PLC Contrai Unit

- ModelC Series Sewing Head with AC Servo Motor COptionally with EFKA Mini Stop Motorl

- Efka 550 W Mini Stop OC motor or Optional: Direct Drive OC Servo Sewing Motor

- Linear Motor Controlled Center Knife System

- Laser Photocell System Measuring the Size of the Pockets flaps and Sewing accordingly

- Four Laser Reference Lines for stitch contrai at Front-Middle& Rear

- Pocket Welt length sizes from 20 mm to 200 mm

- Casella di testoFormaStep Motor Controlled Moving Corner Knife System

- Corner Knives and Connection Unit providing 3 Dimensionai Adjustments

- Programmable start and end back-tack or optionally adj ustable stitch condensing

- Clamp holder far Pocket Flap and Pocket Bag on Left

- Tilt Back Sewing Head allows easy maintenance.

- Swing out folding station for easy access in case of re-threading and bobbin changes.

- Automatic thread Cutting System in the Beginning and End of the Seam

- Upper Thread Monitor and Bottom Thread Monitor

- Micro Adjustment Unit for Right-Left Gramer

- Needle bites sizes are available as 10 mm, 12 mm,14 mm, 16 mm,18 mm, 20 mm

OPTIONS

- Automatic feeder for pocket facing

- Automatic feeder for pocket bag

- Vacuum motor (220 ac 3-2 phase / 0.7-0.8 kw)

- Auto tape feeding system

- Universal Stacker Unit

- Roll-off device for small pieces

ADVANTAGES

- Automatic feeding of pocket facing and pocket bag

- Very precise corner incision

- Maximum quality without mechanic conversion, even in most problematic fabrics

- Fully overlapped working method & easy operation

TECHNICAL DETAILS

- Max. Sewing Speed: 3.000 r.p.m

- Max. Stitch Length: 0,5 o 3 mm Type : 301 ( Lockstitch)

- Needle Distances: 10 - 20 mm standart 8 - 10m / 22-24-26 mm optional

- Connection voltage: AC 230 V, 50/60 Hz

- Air Pressure : 6 bar

DIMENSIONS

- L 140 cm / W 80 cm I H: 120 cm

- Packing Size: 164 cm x 94 cm x 145 cm

- Machine Net Weight: approx. 200 kg

- kg Machine Gross Weight : approx. 240 kg